Project Partners

IWU: Fraunhofer Institute of Machine Tools and Forming Technology (www.iwu.fraunhofer.de)

EFB: European Research Association for Sheet Metal Working (www.efb.de )

KU Leuven - Catholic University of Leuven (www.kuleuven.be)

Sirris The Collective Centre of the Belgian Technological Industry (www.sirris.be )

IWU expects to extend its knowledge about the tempered incremental sheet forming process of light weight materials, enabling IWU to assist and support companies intending to implement the process in production.

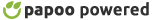

The at Fraunhofer IWU existing, in gantry-style design built CNC milling machine, called Mikromat 30V 5D (Dynapod), will be used for tempered incremental sheet forming (figure 1).

Figure 1: Testing bench Dynapod (Fraunhofer IWU)

The technical contribution which was brought in by the EFB was to organize the expert groups and regular meetings of the scientific committee. This ensured a continuous proper assessment and monitoring with the regular project coordination function. If there will be phases with low achievements or negative results, there will be the aid of highly skilled and experienced experts to give input or a new momentum. EFB can provide a broad database of research data and a small-meshed competence network.

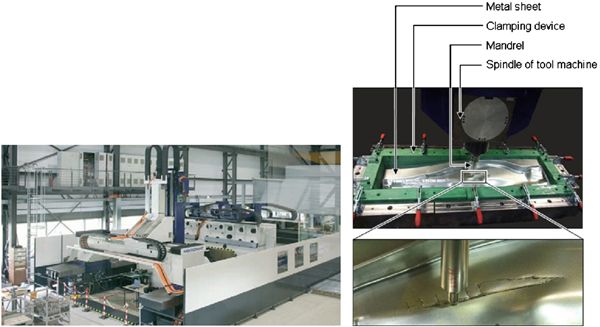

The research group of KU Leuven has a wide experience with Incremental Sheet metal Forming processes in general and with Single Point Incremental Forming in specific. The lab infrastructure of the research group, including a rigid SPIF setup based on a CNC milling machine and an industrial robot based platform for laser supported SPIF as well as an extensive set of in-process measurement and dimensional metrology equipment, will be available for the ISF-Light project support. Specifically the expertise of the research group in heat supported ISF will be indispensable to successfully run the proposed project.

Figure 2: Experimental set-up (KU Leuven)

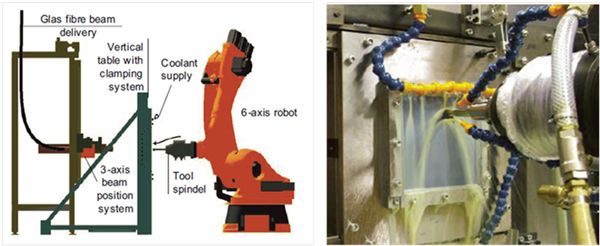

By means of Sirris "Advanced Manufacturing" program, Sirris will bring in extensive knowledge and experience in the fields of sheet metal production technology and mechatronics/automation. Sirris will also bring in its experience in setting up application labs. Recent projects relevant for the present proposal are listed above. Sven De Troy has been working on sheet metal for 5 years and is currently leading the collective research on a robotized bending cell. Rik Belien is a senior engineer, specialised in SME-oriented automation of production processes.

Figure 3: Sheet metal application lab (robotized bending cell) (Sirris)