ACODEPT (Advanced Coil Design for Electromagnetically Pulsed Technologies) is a cooperative project, funded by the European Commission within the CORNET programme. In this project the following 4 research institutes work together:

- IWU - Fraunhofer Institute for Machine Tools and Forming Technology

- BWI - Belgian Welding Institute

- EELAB: University of Gent - Department Electrical Energy, Systems and Automation - Research group EELAB

- MGT: Chemnitz University of Technology - Microsystems and Precision Engineering

They are supported by more than 20 industrial members of the user committee situated in Belgium-Flanders and Germany, most of them being SMEs.

The overall aim of the project is advancing and popularizing the electromagnetic forming technology (EMF) in order to facilitate the manufacturing industry to exploit the process related advantages.

Expertise:

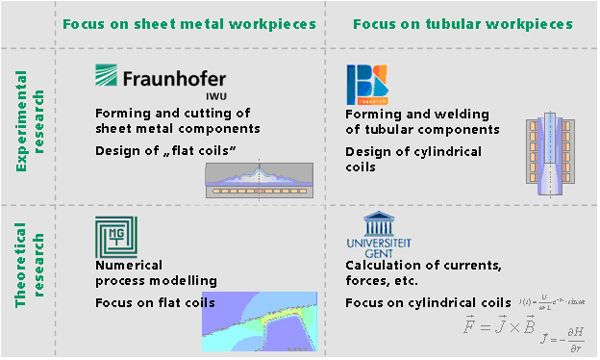

All research performing participants are complementary. BWI and IWU have already gained experience with the EMF technology.

During the previous research activities, BWI has gained knowledge concerning forming and welding of tubular parts made of aluminium, copper, steel and especially concerning dissimilar material joints. BWI possesses a medium-power (50 kJ) electromagnetic pulse equipment capable of forming tubular components (O.D.: up to 80 mm).

The experience of IWU is mainly in the field of electromagnetic forming and cutting of sheet metal components. The institute has a high-power (103 kJ) equipment at its disposal, able to form and cut sheets with a thicknesses < 3 mm. Therefore both research centres complement each other in this project.

Nowadays, an important tool for the acceleration of parameter optimisation or in this case coil development is finite-element modelling. Since TUC has in the past already built up experience in this area, the choice of TUC as partner was evident, also because of the close cooperation between IWU and TUC in past projects.

The expertise of EELAB concerning electromagnetic fields will be required for the design of the coil systems. EELAB studies in detail the electromagnetic or electromechanical phenomena in electromagnetic devices, like electrical machines, power electronic components, actuators, sensors, ... They are able to relate the performance of electromagnetic devices to the behaviour of the magnetic materials of which they are constructed. There was already a successful cooperation between BWI and EELAB in the past projects concerning electromagnetic pulse crimping and welding.

EFB is the project coordinator responsible for managing the project concerning the project group coordination, milestone reviews, financial and technology follow-up, and communication strategy.

The experimental research using pulsed-power equipments will be performed by Fraunhofer IWU and the Belgian Welding Institute. EELAB of the Ghent University will use its expertise in the field of calculation of magnetic forces, current density, etc. in order to calculate the desired shape of the coil systems. Finite-element modelling of the process will be performed by the University of Chemnitz. However, in order to reach the challenging goal of the ACODEPT project intensive cooperation between all project partners is required.

Figure 1: Subdivision of work among the research performing project partners. (© Fraunhofer IWU)