AiF-Nr.: | 262 EBR |

EFB-Nr.: | 30/119 |

Kurztitel: | Strength Prognosis JbyF |

Laufzeit: | 01.04.2020 - 31.03.2022 |

Forschungseinrichtungen: | IWU Dresden |

Projektbeschreibung

The application of mechanical joining technology in various branches of industry such as automotive engineering, construction and white goods has increased considerably over the last 20 years. In order to ensure further growth of these resource-saving joining processes, new users must be able to design these processes quickly and without extensive process know-how. This goal is pursued in the project proposal described here.

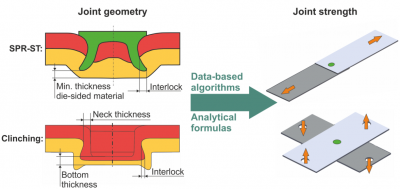

Currently, there are two basic evaluation methods for the design of mechanical joints: on the one hand the evaluation of the joint quality via the geometric characteristics of the joint through cross section analysis and on the other hand the evaluation of the joint via the testing of the strength by destructive testing. In principle, it is known that the geometric characteristics such as interlock or neck thickness are directly related to the strength of the joints but a quantitative correlation for different material thickness combinations has not yet been investigated.

The aim of the project described here is to enable a prognosis of the joint strength for self-pierce riveting with semi-tubular rivets (SPR-ST) and clinching on the basis of geometrical characteristics of the joints as well as the material properties of the parts to be joined. Data-based algorithms (machine learning) and analytical methods will be investigated as prognosis methods. In this way, large experimental series of tests can be saved and the mechanical joints can be dimensioned many times faster.

This project objective is achieved by determining the correlations between joint geometry and strength on a large number of material thickness combinations experimentally and by means of numerical simulation. On the basis of this data, learning algorithms can be trained and the analytical methods can be validated in order to achieve the highest possible prediction quality at the end of the project.