Brief Introduction to Incremental Sheet Forming

Incremental Sheet Forming (ISF) stands for a number of innovative, flexible forming processes in which sheet metal can be shaped into a wide variety of geometries without the need for expensive, dedicated tool sets.

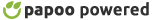

Figure 1: Current and potential fields of application of incremental sheet forming [Ames, J.: Systematische Untersuchung des Werkstoffflusses bei der inkrementellen Blechumformung mit CNC-Werkzeugmaschinen. Rheinisch-Westfaelische Technische Hochschule Aachen, Dissertation, 2008]

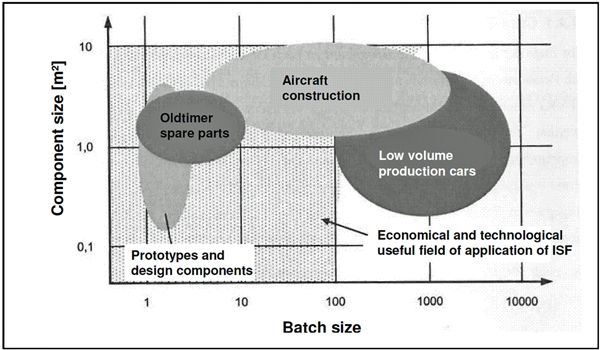

The novel incremental sheet forming (ISF) process with CNC-controlled machine tools allows flexible production of sheet metal parts without need for specially designed forming tools. The principal process is explained by the following figure.

Figure 2: Process principle of incremental sheet forming

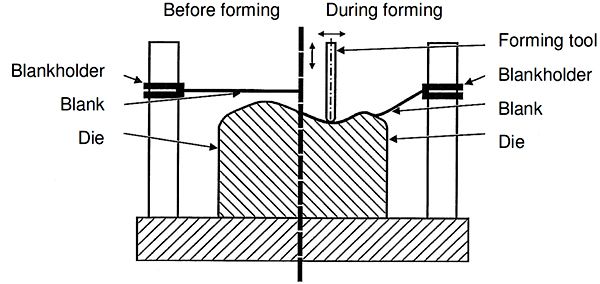

The variants of the ISF process setup also allow to form the sheet without any supporting tools, or with a full or partial die, or with a kinematical counter tool. The following figure shows the different process variants of incremental sheet metal forming.

Figure 3: Process variants of incremental sheet metal forming

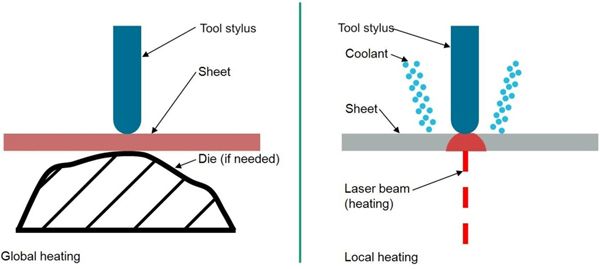

Localized heating of the forming area during the forming process has shown its advantages in different forming processes. So the next figure indicates two different heating strategies. The global heating is used by the Fraunhofer IWU and the local heating is used by the institutions of Sirris and KU Leuven.

Figure 4: Heating strategies

First industrial applications of this novel technology can be found in different sectors. The application of the ISF occurs in different industries. The next pictures show some of the products.

Figure 5: Features on a deep drawn part (Fraunhofer IWU)

Figure 6: Back seat orthosis (KU Leuven)

The main advantages of ISF are:

- Short time-to-market because complex parts can be formed with a CNC program directly generated from a 3D CAD model. ISF eliminates partially or totally the need for tooling efforts compared to traditional processes.

- ISF is cost effective for small to medium sized series as it does not depend on complex and expensive tooling. ISF is typical cost effective up to 300-600 pieces. From that level onwards investing in dies becomes feasible.

- ISF provides giving a high degree of flexibility. It can be adapted to very different freeform geometries, materials and conditions. Changes in part design can be easily and quickly accommodated.

- ISF enables to produce parts of any size. The size is only limited by available hardware. For large size parts serial robots can be used to lower the hardware cost for having a large working area. However, the non-rigidity of these robots induces extra dimensional errors and dynamic effects.

- ISF offers high reproducibility and enables to produce sheet metal parts with improved properties (hardness, strength,...).