Flow Curve JbyF - Standardization of flow curve determination for joining by forming

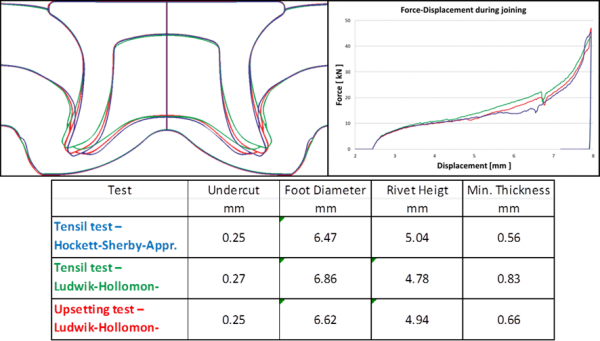

Simulation results of riveting process with varying flow curve approximations [reference: Fraunhofer IWU]

FE simulation is used more and more by SMEs for numerical process development and, through the increasing digitization, also for datamining. The quality for FE simulation of a technological process depends on, among others, the adopted material model and the governing parameters. Technological processes – in this case the mechanical joining processes clinching and self-pierce riveting – put specific demands on model performance.

For an exact calculation of joint geometry and valuation of joint strength, accurate flow curves are required characterizing the range of lower yield stress as well as yield stress for large plastic stains. Due to a multitude of methods determining flow curves and the variety of the models to describe them, problems arise with respect to reproducibility and accuracy in joining by forming simulations. This necessitates time-consuming and expensive calibrations of material parameters.

The aim of this research project is to provide a basis for standardization of determining flow curves tailored for FE simulations in mechanical joining. To be specific, the project is confined to so-called joining by forming techniques. The requirements for identifying suitable material data should be aligned with the material states occurring in joining by forming. The latter information can be deduced from numerical analysis and will be used to select candidate material tests which will be evaluated and developed further.

The ultimate goal of this project is to provide industrial guidelines to identify accurate flow curves for simulating joining by forming processes. To arrive at industrial relevant guidelines, the experimental effort, costs and required simulation accuracy will be considered. Since the project aims at standardization in mechanical joining, an important involves conferring with the industrial partners to reach general agreement on the proposed procedures. Test methodologies, measured material data and state-of-the-art numerical models will be thoroughly compared via round robin tests.

Joining by forming of sheet metal implies local plastic deformation of the base material with the aid of tools and/or additional consumables. The key point is that plastic material flow is induced so that a permanent interlock is created. It is well-known that the final geometry of the joint dictates the mechanical performance in terms of static strength and fatigue life of the joint. As such, it is of utmost importance that the optimal joint geometry is obtained after joining by forming.

In general, the demands for joining techniques increased significantly in the last decade. Today, structures are highly optimized to meet stringent requirements with respect to a variety of performance metrics such as weight, safety and environmental impact.

This project aims at providing guidelines to determine suitable flow curves to increase the accuracy and decrease the complexity for efficient numerical process development in joining by forming.

Partners

Objectives und Work Packages

Results